Riley Register Spares Ltd was officially incorporated as a Company Limited by Guarantee on 22nd May 1987; with Peter Banner, Jim Hennequin and David Styles serving as Directors. The inspiration for forming the company was a decreasing availability of original Riley parts. The aim was to run Spares on a professional basis, with centralised stock and technical support to ensure the highest standards for Register members. RRSL remains a not-for-profit organisation, managed and operated by volunteers. Development of new spares and re-stocking is funded by sales and an annual donation from the Riley Register.

Our Parts

We aim to provide parts at the lowest possible price, but will not compromise on quality. Sales prices and manufacturing costs also need to be balanced against the funds required to maintain a substantial quantity of stock, in a market where minimum order volumes and prices are ever-increasing. To allow members to keep their cars on the road, we need the appropriate level of stock on our shelves, available for immediate shipment.

The team appreciates any constructive feedback that members have to offer, regarding the availability, quality and cost of any of our parts.

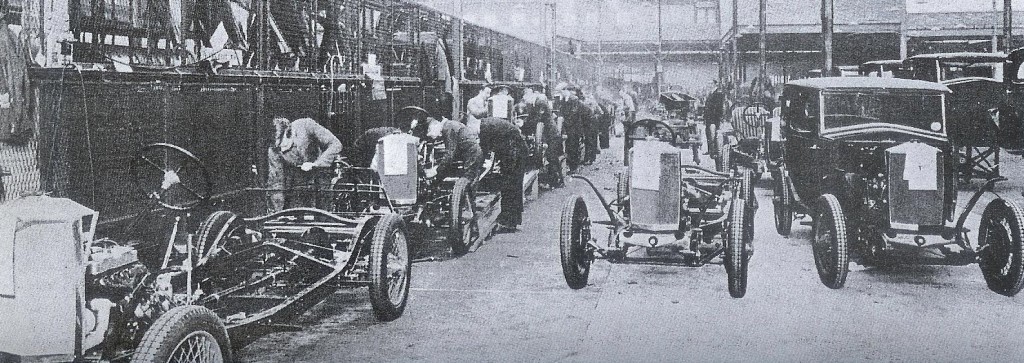

RRSL stock is held centrally and managed by a Storekeeper who is willing and able to offer advice on the correct parts for your car. By their very nature, hand-built vehicles are rarely identical, even if you compare two of the same model produced on the same day, particularly if they were built when the motor car industry was in its infancy.

During the 1930s, Riley continually changed components and specifications, which were often not recorded in their parts books. For example, there are at least twelve different cylinder head part-numbers for the 12/4 engine. Further to confusing catalogues, some cars were built with parts that were available on the factory floor that day and many have been modified by owners in the decades since. The complications related to part identification often prevent owners from utilising the common means for selecting the correct replacement parts for their car, such as the vehicle’s model, age, engine or chassis number. We are aware of many of the variations and have significant combined experience and expertise to help you find the parts you need.

New Parts

Whenever production of a new part is requested, or an existing part needs to be restocked, the team first investigates if that part has become commercially available elsewhere. RRSL sees no benefit in manufacturing Riley spare parts that are already available, unless those parts are deemed to be of poor quality.

Our company operates with strict quality controls and full traceability, delivering fully interchangeable parts to the original Riley designs, often updated to reflect modern manufacturing methods and material specifications. This is achieved in two ways:

1. Manufacturing from Original Riley Drawings

These drawings are copied and updated, where necessary, to reflect current manufacturing practices and materials. We then add any missing dimensions and instructions, because the original drawings frequently lack the information required for manufacture.

2. Manufacturing by Reverse Engineering

Where original drawings are not in our possession, we reverse engineer by inspecting several original components and taking the dimensions, allowing us to create RRSL drawings that would be very similar to the original Riley drawings.

On occasions, we have an original part tested to confirm the required material specification. It is noteworthy that many components have had to change as a result of legislation or the availability of materials. The most obvious example is that we no longer make gaskets with an asbestos filler, as per many of the original Riley gaskets.

History

The Riley Register was founded principally because of the lack of spare parts for Rileys at BMC dealerships. The summary notes of the fist meeting, held at Banbury on 8th June 1954, lists one of the club’s objectives as “to compile a list of spares available and to assist owners in obtaining or disposing of cars and spares”, Elephant Motors (and later Stanley Burville) being noted as some of the sources.

In the 1950s nearly all pre-war Rileys were in everyday use. Initially, members looking for parts were introduced by the Register to others who had knowledge of likely sources. Some members started to buy-up remaining stocks from the dealers, which evolved into consolidated inventories held by at least ten officers, each specialising in different areas. Some even arranged for the manufacture of new parts to fill any gaps.

Bulletin number five of 1955 notes that Register Spares were handled by Alan Humphries of Bristol, although he wasn’t mentioned in number six … and by the publication of seven in January 1956 the responsibility had passed to W.A. Davies. In December 1956, two Spares Secretaries assumed control, one responsible for Nines and 6 cylinder cars, the other for 12/4s. It wasn’t until 1967 that Spares became a formal club ‘service’, with five volunteers administrators.

Vision & Objectives

Our Vision

- RRSL exists for the benefit of the Riley Register membership.

- Register members recognise RRSL as the supplier of choice for quality spare parts, not available from other sources.

- RRSL develops new spare parts using proprietary experience and expertise, to deliver superior products worthy of the Riley name.

RRSL Objectives

- Review requests for new spare parts to justify production, with regard to membership demand, manufacturing costs and available funds.

- Produce accurate engineering drawings and inspect them for correct specification, before placing orders.

- Ensure company finances break-even before receipt of the annual Register donation.

- Maintain and improve a proactive and transparent communication strategy, to keep the Register membership and Committee well informed.